| QTY |

| FOB PRICE |

CIF PRICE

QUANTITY

-

+

㎡

TOTAL COST

$1660| Model : sw96 | Payment Terms : L/C, T/T, Other | Delivery Port : Qingdao port | delivery Time : 13-15 days | Product Advantages : Well and High Quality Control, Prompt Delivery, New Product, Customer‘s Design and Logo are Welcome, Competitive Prices, Earth-friendly Products, Small Order Acceptable, OEM Accepted, Other |

| Material : Default |

| Pcs/Carton : N/A | Packing Size/Carton : N/A | Packing Vol/Carton : N/A |

| N.W./Carton : N/A | G.W./Carton : N/A | QTY in 40HQ : N/A |

| QTY in 40GP : N/A | QTY in 20GP : N/A |

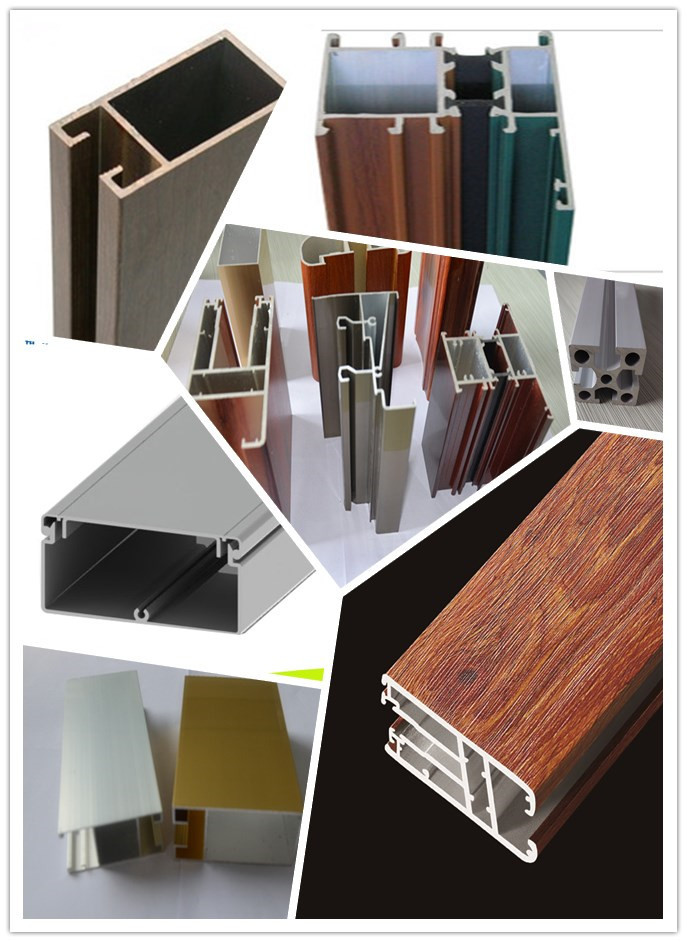

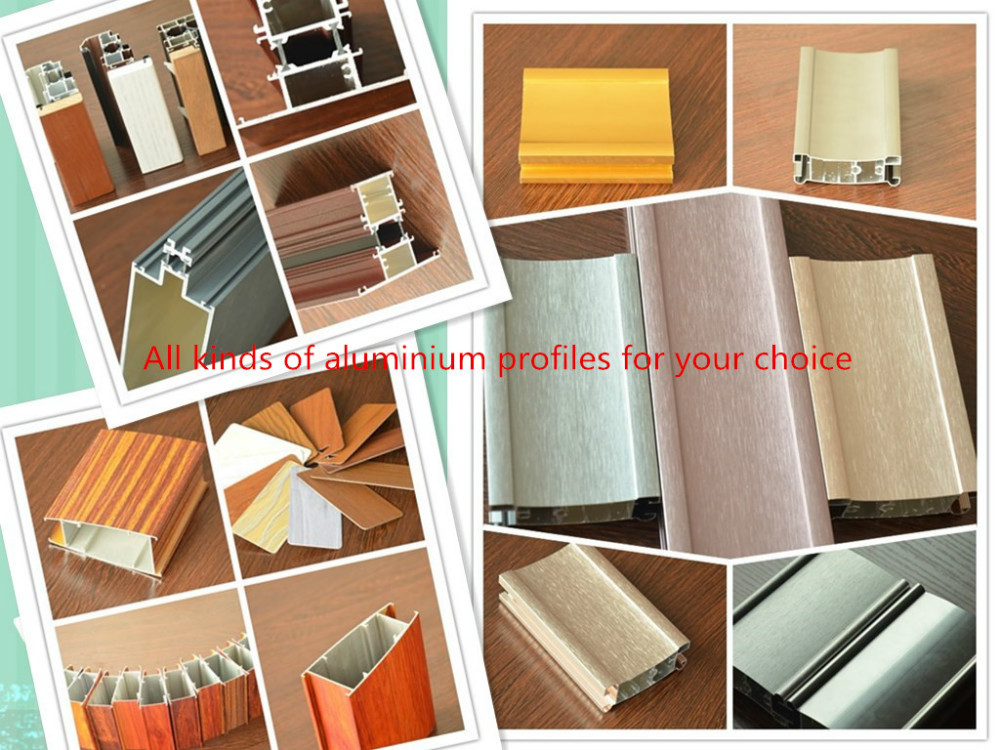

Profiles Advantages

1. Plenty of surface treatments for your choice, such as anodizing, electrophoresis, powder coating.

2. Strict control for surface finish, no scratch.

3. Accurate mold as well as accurate size.

4. Standard alloy composition.

5. Both ends of the profiles are very plain and with no burr.

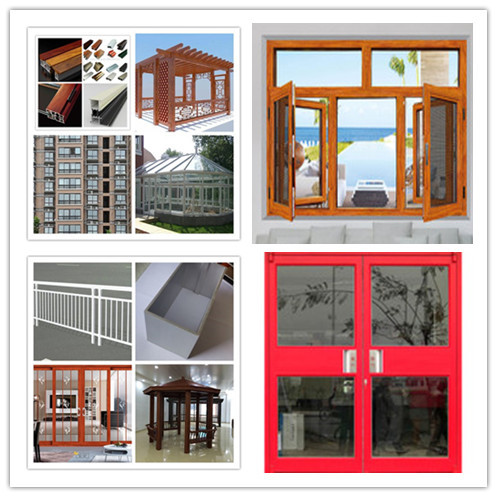

What kind of products and service we can provide:

Part of our products

Company Information

1. Weifang Mario Industrial Trade Co.,Ltd covers an area of 220,000 square meters. It is the second branch of Shandong Xinyudong Aluminium Co.,ltd. which has 13 years manufacturing experience;

2. 30 million RMB registered capital, 3 factories and 1200 employees;

3. ISO9001: 2008, ISO14001: 2004, ISO10012, AA grade standardize corporate;

4. 41 appearance patents, 2 utility model patents, 1 scientific and technological innovation;

5. “China Famous Brand ", “30 assured quality supplier brand ", “Shandong Famous Brand”.

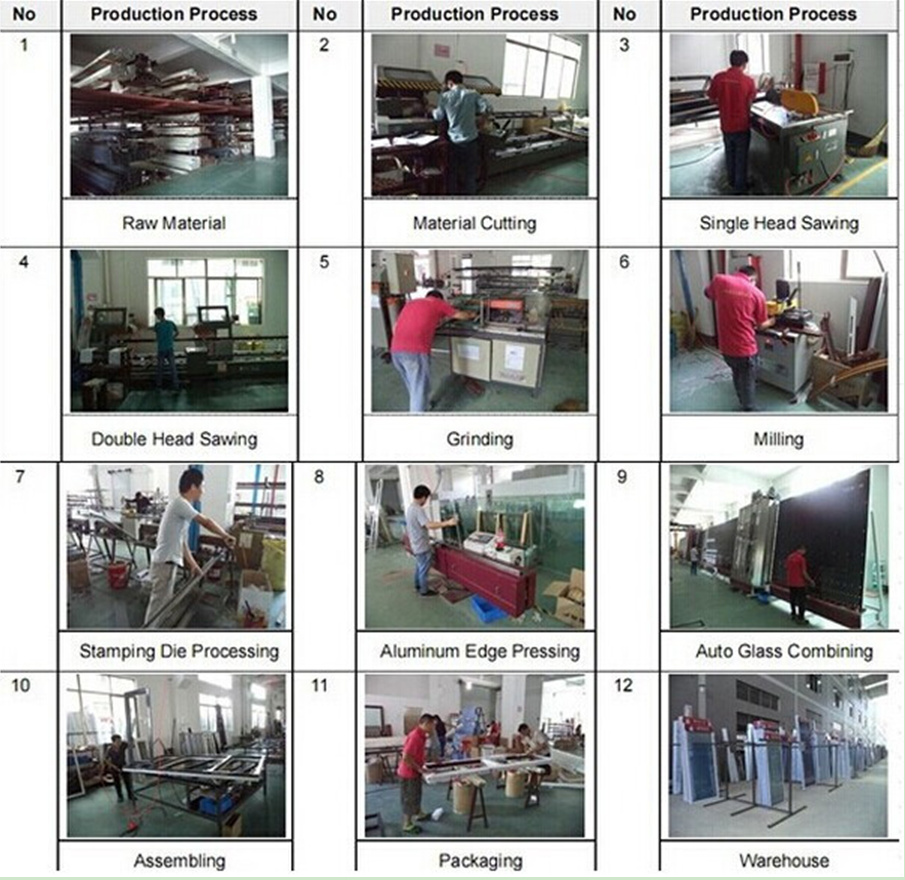

Part technological process of the alu profiles:

1.Melting and casting technological process

Aluminum ingot & alloy → Melting stewing stove→ Eliminating gas → Filtering→ Checkout →

Casting bar → Homogenizing treatment → Checkout Put in semi → Finished products warehouse

2. Extrusion technological process

Aluminum bar →Heating → Extrusion → Chilling → Straightening → Aging treatment → Checkout →

Put in semi → Finished products warehouse

3. Powder coating technological process

Aluminum profile → Added → Degrease 1 → Degrease 2 → Washing 1 →Washing 2 →Film-formation → Washing → Pure watering → Drying → Powder coating → Solidifying preparing → Solidifying→

Undercarriage → Checkout → Put in semi-finished product warehouse

4. Anodizing Technological process

Aluminum profile → Added →Degrease → Washing → Alkali cleaning → Washing → Neutralizing → Washing→

Anodizing → Pure watering → Undercarriage → Hole sealing → Washing → Hot-water washing → Undercarriage

Powder coating Fluorocarbon coating: Use the world leading Wanger coating equipment from Germany is the highest guarantee for product quality!

Heat insulating material production line: In respons to the development trend of environmenental protection market, we have introduced ule-injection style production line from Azone Company(USA) for a qualitative leap on market competitiveness and high value-added of products.

Window and door making process:

Any needs about aluminium windows and doors, welcome to contact me. We can customize according to your sizes and specifications.

Any needs about aluminium windows and doors, welcome to contact me. We can customize according to your sizes and specifications.

• Amanbo Return Policy applies to all orders on amanbo.com.

• If products are not as described, returns are accepted and return shipping fee should be paid by buyer.

• If products are as described, seller has the right to refuse return. Buyer should pay return shipping fee if return require is insisted on.